Water Oil Separator System

Water oil separator system. The offered lamella settlers are specially designed for the filtration of raw water. An oilwater separator from Grainger can help you purify compressed air by helping to filter out the oil in water vapor condensate. The automatic tank gauge receives the feedback.

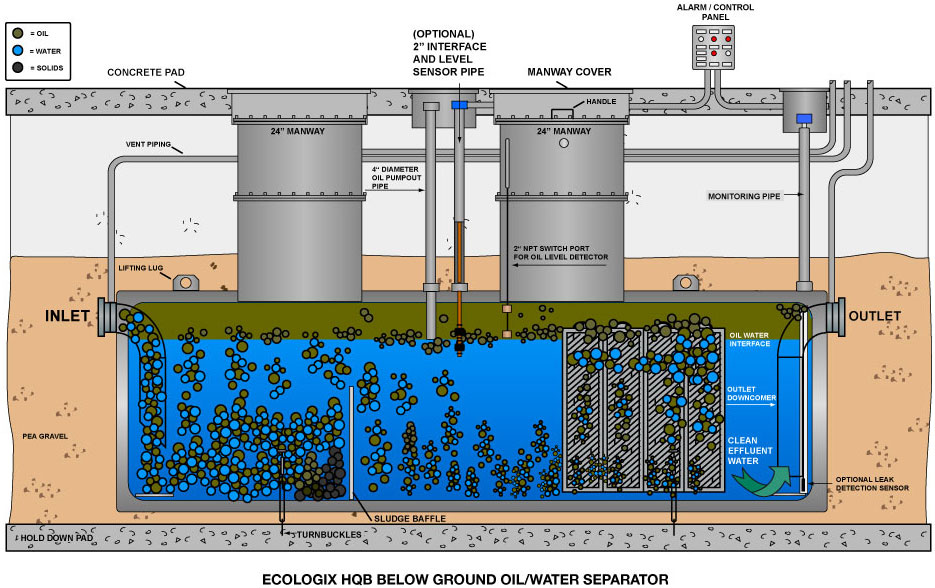

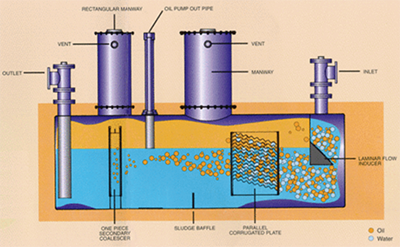

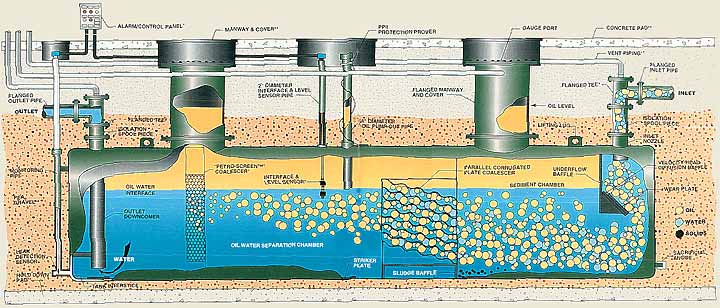

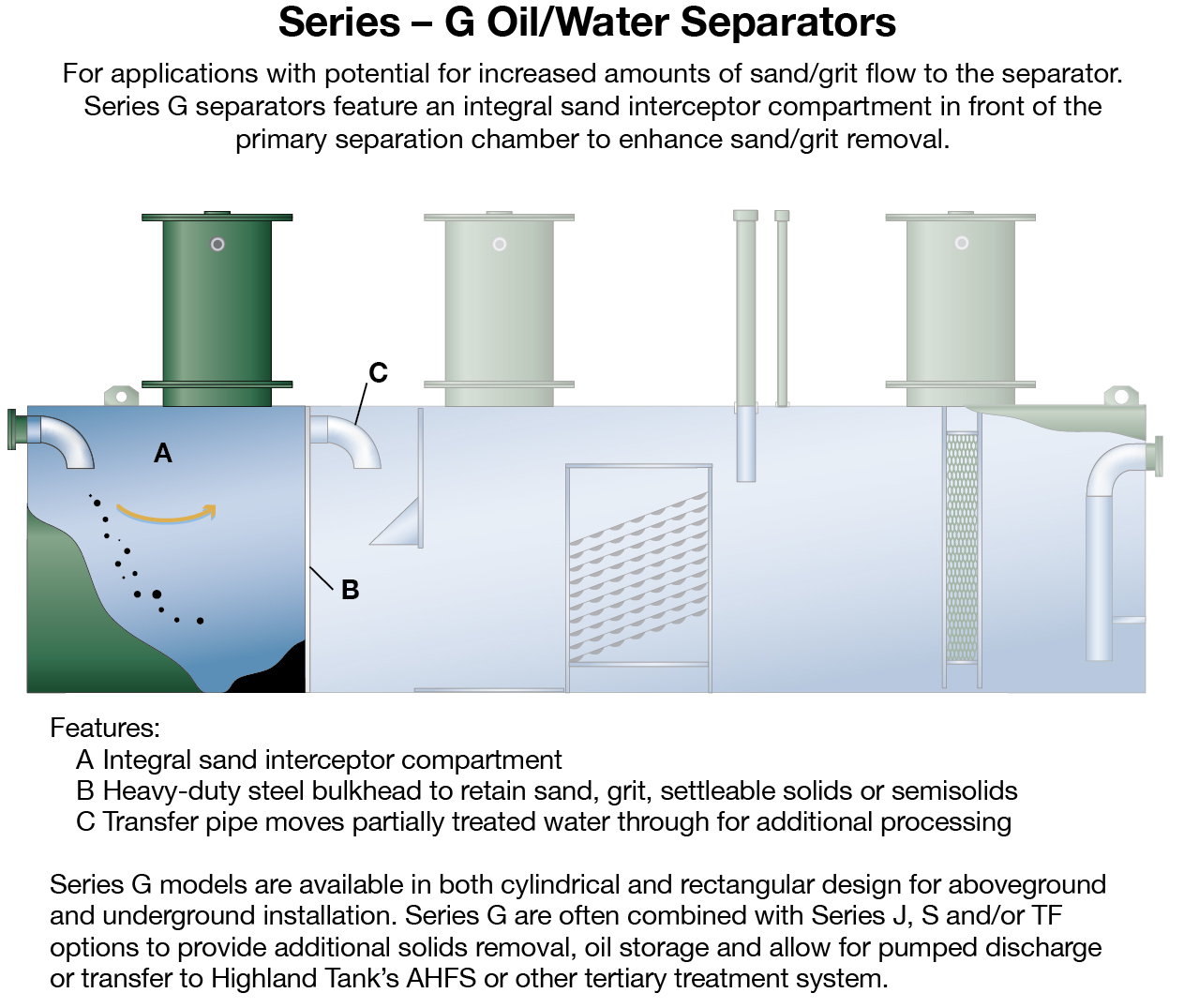

Separators are available in carbon steel single and double wall with a variety of coatings including FRP and sti-P3 coatings. Oil water separator systems work under the physical principal of density. It removes oils grease and hydrocarbons leaving only the non-hazardous water.

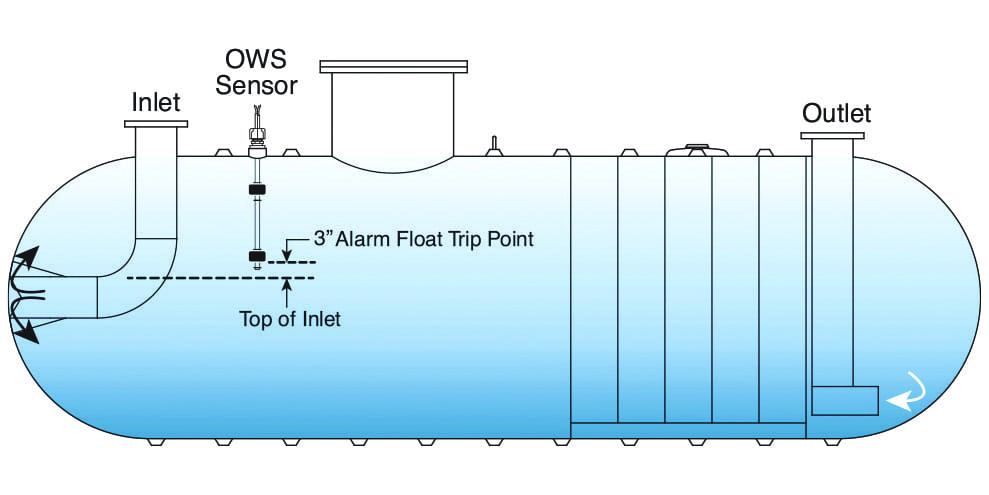

Cleaning the air before it enters the system can extend the life of your compressor and help you reduce the cost of frequent replacement. Our offered lamella settlers are acclaimed for re. Lets begin with the oil water separator sensor.

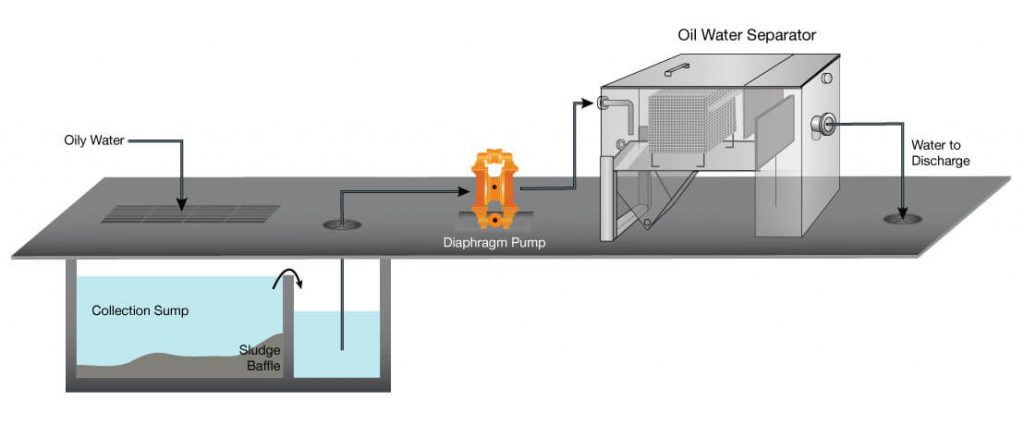

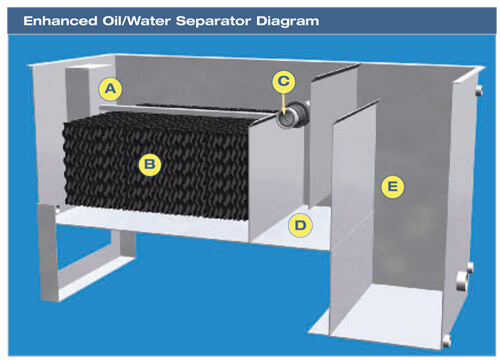

Compact design conserves valuable floor space. There are different kinds of oil water separators and each one has a different capability. An oil water separator in its most basic form is a tank that provides the space and time needed for this separation process to occur.

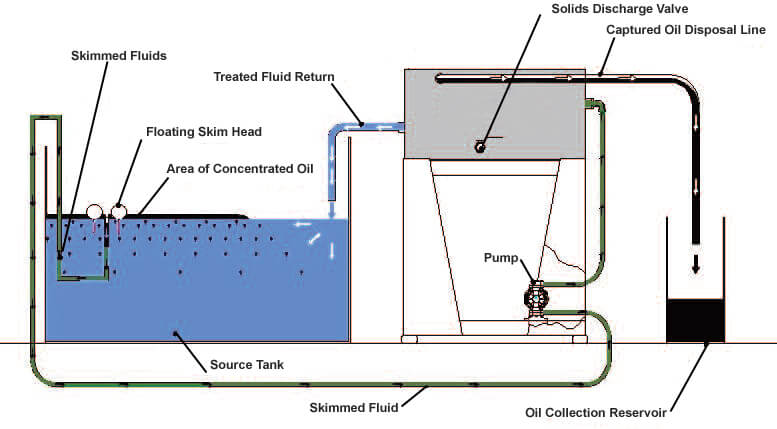

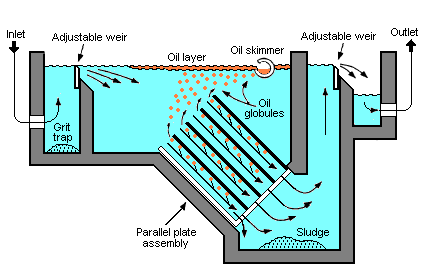

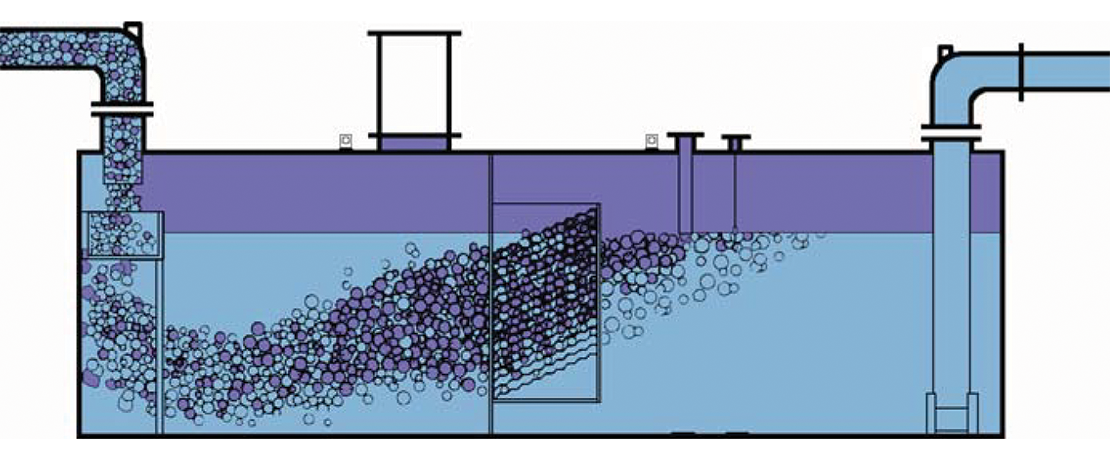

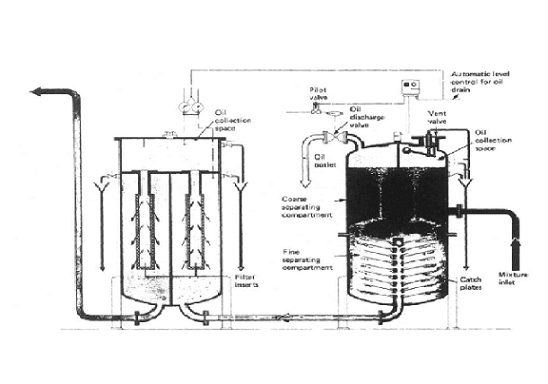

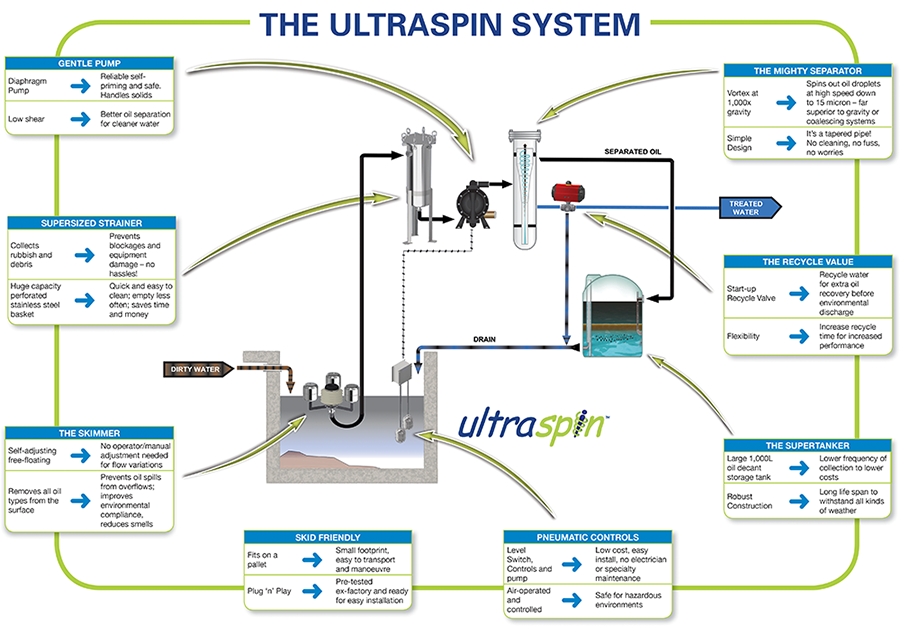

This is to prevent them entering the local environment and stop them polluting your site. The Pollution Control Systems OCS Series oil water separator with its coalescence principle of operation offers the user a number of advantages in treating free and dispersed oil. To do this the oily waste water is pumped tangentially into the separator which forms a powerful vortex and huge centrifugal forces.

We are one of the leading manufacturers and suppliers of TUBE SETTLER. Low maintenance and operating costs. Any business that plans to discharge oily or sediment-laden wastewater to the sewer must install use and maintain an oilwater separator.

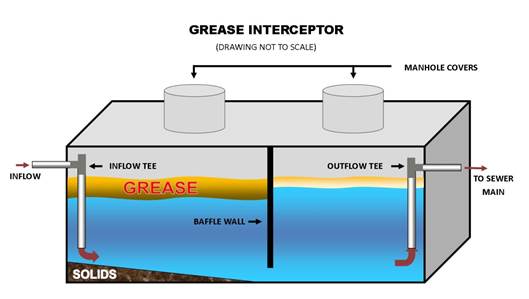

Oil is less dense than water and the two liquids are immiscible. Mercer supplies a line of high-performance cylindrical below-ground oilwater separators from 50-5000 gpm 10-1000 m3h.

Low maintenance and operating costs.

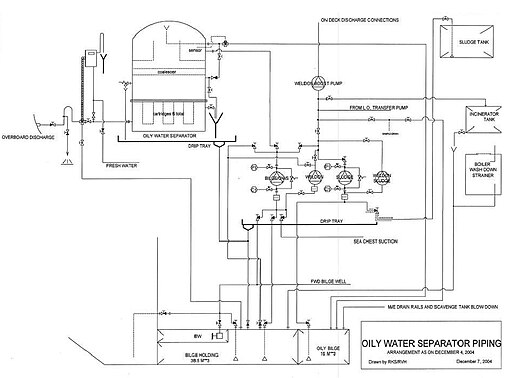

It removes oils grease and hydrocarbons leaving only the non-hazardous water. The Oil Water separators comprise of several parts- each designed to play a special role in the entire separation exercise. Lets begin with the oil water separator sensor. Our offered lamella settlers are acclaimed for re. Mercer supplies a line of high-performance cylindrical below-ground oilwater separators from 50-5000 gpm 10-1000 m3h. An oil water separator is a piece of equipment used in wastewater treatment processes for separating oil and water mixtures into separate components. The wastewater can then be disposed of safely in drainage. Properly designed installed and operated oily water separators provide a treatment system for handling oily wastewater that prevents the entry of. The API Series steel gravity OilWater Separators are designed per American Petroleum Institute API standards for above and below grade applications.

Lets begin with the oil water separator sensor. An oil water separator is a piece of equipment used in wastewater treatment processes for separating oil and water mixtures into separate components. This difference in specific gravity causes oil to rise to the surface of water forming two distinct layers. API Oil Water Separator. It removes oils grease and hydrocarbons leaving only the non-hazardous water. Choose the size and power level that can fit your compressed air needs. Unit operations that are added to OWScentrifuge-based bilge separator systems include.

Post a Comment for "Water Oil Separator System"